|

Théorie De La Compression Sur Un Moteur Théorie De La Compression Sur Un Moteur

Compréhension De Son Focntionnement Compréhension De Son Focntionnement  |

*** Décembre 2009 *** (Traduction en cour de réalisation... dés que j'ai un peu de temps...merci pour votre patience ...Sauf si vous lisez l'anglais techniques sans soucis...tant mieux pour vous !)

(By David Vizard)

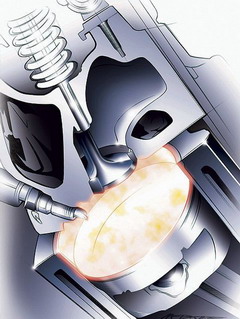

Compression Comprehension : A four-stroke (or four-cycle) engine is so called because in the process of producing power, the piston passes up and down the bore four times. These strokes or events are the induction, compression, power and exhaust stroke. As you may suppose, the effective function of all are important toward producing a high-output engine. But of the four, the compression stroke has far less obvious but more far-reaching implications on an engine's optimal spec and its subsequent success as a power producer. Obviously the principal idea of the compression stroke is to compress the intake charge as effectively as possible, and to do so with minimal leakage. We need to bear that in mind as we move on, because there are two principal factors associated with the compression ratio. The first is the calculated ratio, which we will refer to as the geometric or static ratio. The next, and equally important, factor is how effectively, and to what degree the physical components of the engine compress the charge into the combustion space. In essence what we are going to look at here is a measure of how effectively our theoretical compression ratio is translated into real world pre-combustion cylinder pressure. This is highly influenced by such things as ring and valve seal and valve opening/closing events.

You may well have heard the term Compression Ratio (CR) many times, but may not know exactly what defines the CR or how it's calculated. If so, you need to refer to the nearby sidebar. Also it may all look like we are treading a well-worn path here, but it's worth taking a quick look at the four strokes, as each of the other three is intimately tied to the compression stroke. Check out the four-stroke sequence of events in the sidebar. Every one of these strokes must accomplish its goal effectively for an engine to be able to produce a high output. Let's start with the intake stroke. The more efficiently the cylinder is filled on the induction stroke, the more rpm the engine can turn before it "runs out of breath." The better the intake filling is, the higher the pressure achieved on the compression stroke. This, along with as high a compression ratio as the fuel will stand, means significantly higher pressures on the power stroke.

Moving on to the compression stroke itself, we find that the higher the compression ratio is, the higher the resultant combustion pressure is. Not only that but the charge also burns faster, thus necessitating less advance for an optimal burn event. In addition to this, the amount of residual exhaust remaining in the chamber at the beginning of the intake stroke is less. This reduces unwanted intake dilution by the exhaust. These are the most obvious power-enhancing factors, but they are not the biggest influencing factors by any means. There are other less obvious but more influential implications that we will deal with later when we look at the CR and compression factors in detail.Next is the power stroke. Every bit of power the engine will develop is made on this stroke. We need to make sure everything that happens before, during and after this stroke either enhances it or, at the very least, has minimal negative impact on it. That means not only sealing up the cylinder in the first place, but also making sure it does not leak throughout the power stroke and that its sealing ability is not at the expense of high ring-to-cylinder-wall friction.Last of the four strokes is the exhaust. Here we need to make sure that cylinder emptying is done without undue pumping losses. Any pressure remaining in the cylinder while the piston is on the way up the bore is negative power. As far as exhaust stroke efficiency is concerned, having a higher CR can, as we will see later, lead to significantly reduced pumping losses.

Thermodynamics Made Easy :

It takes the barest of mental agility to appreciate that increasing the CR will raise cylinder pressure, thus causing torque output throughout the rpm range to simply follow suit. What is less obvious is that the increase in output from the higher CR comes about largely due to an increase in thermal efficiency. The thermal efficiency is a measure of how effectively the engine converts the heat-generating potential of the fuel, when burned with an appropriate amount of air, into mechanical power. To explain all this (starting from the raw fuel and air to the output at the flywheel) is rather more complex than we have the space (or inclination) to deal with, but no matter, as the most pertinent and relatively simple part applying here is not. To more clearly appreciate how the thermal efficiency is improved, we need to consider what is essentially the opposite side of the coin to the CR. This is the Expansion Ratio (ER) and describes what occurs as the piston moves down the bore on the power stroke rather than what happens as it moves up on the compression stroke.

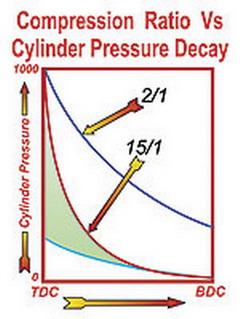

Take a look at the Cylinder Pressure Decay chart and then let's go through the characteristic difference (computed taking into account typical heat losses) between a high-compression cylinder versus a low-compression one. For a moment, let us imagine that both the 15:1 and the 2:1 cylinders start off at TDC with 1,000 psi. As the piston of each cylinder moves down the bore, the drop in pressure follows a distinctly different line. The 15:1 cylinder drops pressure much faster than its 2:1 counterpart because of its more rapid change in volume. It only has to go down the bore a short way for the original volume to have doubled, whereas the 2:1 cylinder must travel to the bottom of the bore to double its original volume. At the bottom of the stroke, the 15:1 cylinder has dropped down to about 25 psi above atmospheric whereas the 2:1 cylinder is still at some 260 psi. In simple terms the high-compression cylinder, when the exhaust valve opens at BDC, is only dumping 2.5 percent of its original pressure whereas the 2:1 cylinder is dumping 26 percent!

Up to this point we have assumed that both cylinders start with 1,000 psi. In reality, the best that the 2:1 ratio cylinder would generate is about 200 psi. That produces the lower curve (light blue line) on our graph. Both the 2:1 and 15:1 cylinders will draw in about the same amount of fuel and air. But we can see that the 15:1 cylinder has more area under the curve by an amount equal to the green shaded area. The addition of the green shaded area under the curve amounts to about a doubling of the power output from the same amount of fuel and air. That means from the same heating value of fuel we have doubled the thermal efficiency and in so doing extracted twice the power.

From what we have covered so far, you can see why a high-compression cylinder produces better power and fuel economy. It is not solely because the charge is squeezed harder and the resulting combustion pressure is increased, but also because the higher expansion ratio allows more energy to be extracted from the original high-pressure charge.

If a 2:1 and a 15:1 cylinder start at the same pressure, the 15:1 cylinder's pressure decays at a far higher rate and in so doing delivers the power to the crank mostly before 90 degrees after TDC is reached. Unless supercharged, a 2:1 cylinder would only achieve about 200 psi and as such, the difference in power be-tween the two ratios would be represented by the shaded green area.

This formula for the thermal efficiency of the Otto Cycle may not look like much, but when all its implications are applied it can be said to be responsible for about 150 hp of the total produced by a 500-inch Pro Stock engine.

To find out what a higher CR may be worth, locate the existing ratio in the left-hand column. Follow the line across until you reach the appropriate column with the new CR at the top. The figure in the intersecting box represents about the minimum percent increase that will be seen.

Because the intake valve does not close at BDC, the increase in static compression delivers a far more effective increase in dynamic compression. Here some typical intake valve closing points are shown for three different cam duration figures.

When used in conjunction with a bigger cam, increased compression can work wonders for the entire curve. When a 265-degree cam (gray curve) was substituted for a 285-degree cam (blue curve), a substantial drop in low-speed output was seen. Raising the CR from 9:1 to 12:1 recovered almost all the lost low end and gave a further increase in top-end output.

Simple Theoretical Power Gains : The nearby formula (see Fig. 1) can be used to calculate the theoretical power gains seen from raising the CR and the chart will save you the effort of calculating those gains. This formula does not take into account the inevitable heat losses, so to allow for this the value of "K" is commonly reduced from 1.4 to 1.3. Using this value we find that, changing nothing else but the compression, output pretty much follows the trend dictated by the formula until about 15:1. From there on up, chemical reactions brought about by the high temperatures and pressures generated absorb heat and only deliver it back to the cycle so late in the expansion event as to serve no useful purpose. Because of this, many learned textbooks will tell you that trying to utilize CR past about 14:1 is a fruitless exercise. But this only applies if no other changes are made to the engine. If, as we shall now see, the side benefits of ultra-high compression are taken advantage of, the situation takes a complete about face.

In the real world, we normally find that theoretical increases are not usually seen in practice because of losses which, to simplify already complex theory, we have ignored. For high-performance engine, part of what has been overlooked by the simple thermal efficiency equation works to produce results far better than theorized. In other words, all the figures in the chart (Fig. 2) are on the low side. For instance, a mildly modified 9:1 350 small-block Chevy would make about 380 lb-ft of torque. Based solely on our thermal efficiency formula, raising the compression to 12:1 should bump that figure to 397 lb-ft. In practice, that number is usually exceeded and the bigger the cam involved, the bigger the gain. To understand how more can be had, let's look at the effect the cam has on the situation. At lower rpm we find that the static CR is never realized because our thermal efficiency formula makes the assumption that the intake valve closes exactly at BDC prior to the start of the compression stroke. This does not happen in reality.

At low rpm, port velocity and pressure waves are too weak to produce any cylinder ramming. Couple this to the fact that even a short cam of some 250 degrees of off-the-seat timing will not close the valve till about 50 degrees after BDC. Fig. 3 shows the typical extent of piston motion back up the bore before the intake closes for three cams. Because of the delayed intake closure we find that during the period the piston moves up the bore from BDC until the valve closes, a significant amount of the induced air is, at low rpm, pushed back into the intake manifold. This means the volumetric efficiency (breathing efficiency) and thus the effective displacement of the cylinder is well below 100 percent. In other words, a 100cc cylinder with a static CR of 10:1 may only trap 75cc of air. This means the dynamic CR, at about 8.5:1, has dropped well below the static CR of 10:1. The bigger the cam, the more this effect comes into play.

An example here will show just how much influence the delayed intake closure has on the dynamic CR. Let us take three different duration cams, all having a 108-degree Lobe Centerline Angle (LCA) and all timed-in at 4 degrees advanced. Along with this let us say our static CR measures out at 12:1. With a 250-degree duration cam, the dynamic CR will be in the mid- to low-11s. For a cam of some 275-degrees duration, the dynamic CR will drop to around the mid 10s. Because of the piston/con rod crank geometry, the piston tends to move much more slowly around BDC. This works in our favor for shorter cams, but the piston quickly moves out of this sweet spot, so once we get much past about 280 degrees we had better have a decent dynamic CR. To give you an idea to what extent this occurs, we find that with our example a 300-degree race cam used with a static CR of 12:1 has a dynamic CR of only about 8.3:1. This snippet of info should bring home the importance of having sufficient CR for a big cam. If it doesn't, then maybe the dyno test results in Fig. 4 will. These are some tests I did with the 2-liter Ford Pinto series of cams I designed for Kent Cams in England some years ago. I realize that very few of you drive Pintos, but the two-liter version of this engine, because of its geometry, reacts about the same as a typical small-block Chevy, so the results do directly apply. From these results we see that with a 9:1 CR, a 260-degree cam produced (the gray curves of Fig. 4) some decent results from low rpm on up. As expected, it started to drop torque by the time 5,000 rpm was being approached, and power peaked out at just shy of 140 hp. This cam was then substituted for a 285-degree cam. On the same 9:1 CR (blue curves of Fig. 4), this bigger cam dropped 38 lb-ft of torque at 1,750 rpm. That amounts to a 32 percent reduction. The extra duration did not start to pay off until 3,750 rpm. From there on up the bigger cam paid off by delivering an increase in peak torque of 4 lb-ft and almost 26 hp. At this point the head was milled to bump the CR to almost 12:1. The results of this move are shown by the green curves in Fig. 4. As you can see this increase in compression recouped almost all the low-speed torque that was lost. On top of this the big cam/high compression combo produced an increase of 15 lb-ft and 33 hp. Stepping that result up to a 350-inch engine, the numbers look more like 40-plus lb-ft extra and 95 hp. So are these numbers realistic? Sure they are. I have seen well over 100hp increase from a 355-inch small-block Chevy with 25 degrees more cam duration, 100 thousandths more lift, and 2 points more compression.

The big increases seen with a combo of more compression and cam are easier to understand when we go back to the basics. If you check the numbers in the chart (Fig. 3) you will see that the biggest gains from a compression increase happen when moving up from a low compression to a higher one. Going from 8:1 to 10:1 is worth a theoretical 3.7 percent, whereas raising the compression the same two points from 11:1 to 13:1 is only worth 2.5 percent. This means the bigger the cam, the more responsive it is to an increase in CR, especially in the lower rpm range. About now there are going to be some of you who are wondering whether the engine you have just built and installed has enough compression for the cam you chose. Assuming your engine has good ring and valve seal, a simple way to determine whether or not this is the case is to check cylinder compression pressures. With the ring package and bore prep procedure I use, my own engines are almost always near zero leakage and we will look how to achieve that later. If the cylinders are sealing up well, I look for 190 psi as a lower limit with preferably 200 psi as a target when using 93-octane fuel. For every octane number less than 93, the compression pressure needs to be about 5 psi less to avoid detonation under normal circumstances. As good as a compression test may be, to determine whether or not the cam you are using is accompanied by adequate compression hinges, to a certain extent, on how well the rings and valves seal up. The best way to establish that is to do a leak-down test. This will require a leak-down tester and a source of compressed air at about 100-110 psi. Just how much leak-down is acceptable is open to debate. With the rings and bore prep I use, I expect no more than 1 percent and something close to zero is what I normally see. But the average street engine is rarely that good, so we will talk in terms of more practical numbers. If your cylinders check out at 7 percent or less, then you're okay. With such a cylinder, let the compression gauge go 8 pumps and use that as a reading to determine your cam/compression compatibility. If ring seal is such as to show 10 percent leak-down, then it's borderline for a high-performance engine and compression readings will be artificially low. If the leakage is 15 percent or more, then maybe you should consider new rings as a performance-enhancing move as much as a reconditioning one.

Intake-To-Exhaust-Valve Ratios :

The controlling factors influencing the best intake-to-exhaust ratio for maximum output (and this does assume all the available space for valves is used) has been a much-debated subject that, for the most part, has left the reader little or no wiser. The often-touted 75-percent rule is usually accepted without further question. In reality, the value is far from fixed. The optimum intake-to-exhaust ratio could range from as little as 0.75:1 (for a low CR supercharged engine) to as much as 1:0.6 (for a very high-compression naturally-aspirated engine). What is usually not appreciated here is that the CR is, for the most part, the controlling factor. Because the high-compression cylinder delivers energy to the crank much earlier in the power stroke, there are implications we can take advantage of. The most obvious is that the exhaust valve opening can be made earlier and held open longer. This can be done for improved high-rpm output without significantly impacting the engine's low-speed output. The rule here then is that the higher the compression ratio goes, the smaller an exhaust valve is needed to get the job done. This in turn leaves more room for a larger intake.

When we are forced to use a lower compression, such as in the case of a supercharged engine, then the exhaust valve needs to be left on the seat until later in the power stroke so as not to unnecessarily dump usable cylinder pressure. Because it has to open later, there is less time to blow down the exhaust, so a larger valve must be used at the expense of the intake. That 75-percent exhaust-flow rule mentioned earlier works for engines in the 10 to 13:1 range, but by the time we get to 16:1-plus, the optimum is to have the exhaust flow about 65 percent of the intake.

Shown here is a typical compression tester. With the engine warm, open the throttle a little and crank the motor. Keep cranking and check to see what pressure is registered on the eighth compression stroke

Seen here is a Total Seal leakdown tester. To use this, an air supply of a little over 100 psi is required. The percent leakdown is the measure of the calibration pressure (100 psi) versus the pressure the cylinder can sustain after leakage has taken its toll.

This is a derivative of one of Ford's most successful race heads ever: the D3. On a 15:1 350-inch drag race engine, it is capable of 900-plus hp from a single four-barrel configuration. The point to note here is that all the exhaust from such an output still goes through a 1.6-inch exhaust valve just as we see on a typical street 350. By contrast, the intake is almost 2.25 inches in diameter so the size bias is much more toward the intake than is seen on a low-compression engine.

If the dome has excessive intrusion into the combustion chamber it will inhibit flame travel. Out of the box, many pistons are shaped as per the line arrowed. This needs to be removed as shown to promote more effective combustion.

Here is why a high compression ratio in a hemi configuration can fail. With a high dome the combustion chamber ends up resembling the skin of an orange. This has about as bad a surface-area-to-volume ratio as can be had and effectively quenches flame travel.

Here is the new Chrysler Hemi head, which is often cited by Chrysler purists as less than a true Hemi because of the quench areas on each side. What should not be overlooked here is that this, in every respect, is way better than a true Hemi.

Big-block Chevys thrive on high compression, but it is important to keep in mind that the full benefits of a high CR can be lost if the piston crown shape is not conducive to effective combustion...

...Here we see KB's new high-po big-block forging. Note how the area around the spark plug location (arrowed) has been formed to promote flame travel

If the CR being sought can be achieved with a dished piston such as this JE item shown here, so much the better as going this route usually guarantees an unimpeded flame travel.

If the CR being sought can be achieved with a dished piston such as this JE item shown here, so much the better as going this route usually guarantees an unimpeded flame travel.

Note the minimal raised crown on this Calico-coated Lunati piston. It was used in a 441-inch small-block Chevy to achieve a 13:1 CR in conjunction with this chamber form (also coated) in a conventional 23-degree heads.

...On 100 Octane fuel, it delivered 600 lb-ft and over 700 hp and was street drivable.

Top-notch ring seal starts with an equally top-grade bore and hone job. Always have the bores honed with a deck plate and with a finish as recommended by the ring manufacturer.

Maximizing High Ratio Results :

At this point it is pretty clear that making the most of the potential that can be had from high compression is a goal worth pursuing. But as the ratios sought get higher, counter-productive problems can begin to arise. Probably the most commonly seen of these is due to the final combustion chamber shape achieved when all the stops have been pulled out. The problem here is that as ratios much above about 10:1 are required, the only way to further minimize the volume after maximizing head milling is to have a raised crown piston. Up to a point, this is okay, but if the crown intrudes into the chamber too far, it can severely compromise the flame travel, resulting in a very ineffective combustion process. As to how much can be lost, suffice it to say I have seen a hundred horsepower disappear because of a piston crown intruding an eighth inch too much. The rule here is that unless you know what combination of chamber and crown form works or are prepared to do the necessary R&D, don't go overboard on crown intrusion into the chamber. For typical small-block V-8 from Chevy, Chrysler or Ford, a good rule of thumb is to use no more than 100 to maybe 125 thousandths crown height in your quest for a high CR.

If you are forced to stick with conventional heads patterned after the OE-style head, then big-block Chevys can be something of a law unto themselves. Compared to a regular parallel-valve engine, the chamber is somewhat less than conventional. A big-block Chevy will tolerate a substantially raised crown before the trade-off starts to cancel out potential gains. The key is to make sure the raised section of the crown does not too closely shroud the spark plug.If achieving the CR results in an overly intrusive crown, there is an alternative solution. Instead of trying to reduce the capacity of the combustion chamber, try increasing the capacity of the cylinder. Either a bore or stroke increase will do this. For instance, if you were looking to achieve say 10.5:1 with a 454, it will take a maximum head-milling job plus a piston intrusion approaching half an inch to achieve. The head-milling job is going to mean a lot of possibly expensive manifold machining to re-align the ports. An easier and only minimally more expensive way would be to install one of Scat's cast steel 4.25-inch stroker cranks. This, in conjunction with a 100-thousandths overbore will not only deliver 505 inches, but also allow a 10.5:1 ratio to be achieve with a very acceptable crown height of about 150 thousandths. The same kind of move can be beneficially applied to small-blocks. Using an inexpensive stroker crank in a 350 Chevy not only delivers extra cubes, but also allows a 10.5:1 CR to be achieved with flat-top pistons and regular un-milled 68cc heads. My extensive testing has shown Total Seal rings can produce zero leakdown and can continue to do so for as much as 100,000 miles. Here is how they work: Firstly, the gap for the lower ring is on the opposite side of the bore where it is sealed off by the upper ring. Gas pressure, communicated from the top side of the piston, passes down and through the gap as shown or through the radial gas ports if the piston used has them. This pressurizes the backside of the ring, ensuring firm contact with the cylinder wall. Because both upper and lower rings are virtually in contact with the bore, no leakage route exists.

Let's talk quench clearance for a moment. The quench clearance is the distance the deck of the piston is from the cylinder head face at TDC. Loose (wide) quench clearances can actually promote detonation. The worst to have for most conventional-style wedge head V-8s is about 100 to 125 thousandths. Reducing this clearance (by block milling or a taller piston) can actually stave off detonation by a substantial amount. As to how tight the quench can be made depends on how flexible the block and bottom end assembly is and how much thermal expansion has to be allowed for. With good steel rods and crank, the net clearance can usually be taken down to 30 thousandths. With a typical FelPro gasket of some 40 thousandths thickness this will mean the pistons come out the block by 10 thousandths.

If quench is so good at suppressing detonation and allowing the use of higher CRs for more power and better mileage, why doesn't the factory make it tight to start with? In a nutshell the answer is emmissions. Tight quench over too large an area (such as seen in a typical small-block Chevy or Ford of the pre-1997 era) causes unburned hydrocarbon emissions to go up. However, quench is a key element toward fast burn and this in itself can lead to the successful use of a higher CR just as we see with the LS1/6 family of engines. For modern engines, the trend has been to use a more open chamber with less quench area, but to make the quench action more active by tightening it up as necessary. Although high compression benefits fuel mileage, it can bring about a dramatic increase in oxides of nitrogen, which is the primary cause of smog. Offsetting this is the fact that because a fast-burn chamber requires less ignition advance, the amount of cylinder pressure and temperature generated to develop a certain amount of output is less, so in that respect oxides of nitrogen are lowered. In all, optimizing quench clearance and quench area (as a percentage of the bore diameter) is something of a tight-wire act done at the OE level and you may ask if we should worry about this for our street machines? The answer is "no." Some high-flow cats and a well-calibrated fuel delivery system will keep emissions adequately in check.

Gas porting is a technique whereby compression and combustion pressure is communicated to the backside of the ring, thus pressing it more firmly against the cylinder bore wall. Piston deck-located ports such as seen here work well for a drag race engine but plug up too easily for an endurance engine.

Gas porting is a technique whereby compression and combustion pressure is communicated to the backside of the ring, thus pressing it more firmly against the cylinder bore wall. Piston deck-located ports such as seen here work well for a drag race engine but plug up too easily for an endurance engine. Containing the Pressure :

Having a high compression ratio brings about greater demands on cylinder sealing. The higher the pressures involved, the more attention needs to be paid to details. The first part of the equation toward sealing up the cylinder is to make sure your machine shop hones the block right. This should involve the use of a deck plate to simulate the distortion brought about by the stresses of head bolt tightening. Next, make sure your machine shop is aware of the type of piston ring material being used so they can apply an appropriate finish. Then give the bores a good rub down with a new Scotch Brite pad and plenty of Gunk engine cleaner. After that, scrub (with a stiff brush) the bores with a strong liquid detergent and hose off with hot water. After you are sure they are clean and grit-free, hose the block down and spray the machined surfaces with WD-40 to prevent rust.

Now that the bores are ready, let's look at the rings that will ride on them. With modern oils, ring wear is hardly the problem it used to be. This being the case, use the thinnest rings practical. Many older-style V-8 pistons are still in wide production. The majority of these pistons still have 5/64-inch compression rings. There is no good reason for using these wider rings. A 1/16-inch or even 43 thousandths wide rings are what you should go for. Be aware that the wider the ring gaps are, the greater the loss of cylinder pressure and consequently power. Add to this an increase in blow-by into the crankcase. This contaminates the oil faster and will necessitate more frequent oil changes. If you are going to stick with conventional rings, then gap them to the minimum recommended by the manufacture. If you can afford them, go with Total Seal rings as they really do deliver near 100-percent sealing capability and equally important, they maintain it over a substantially longer period then even the best regular type rings.

Seen here is the mode of operation for both vertical and radial gas ports. The vertical gas ports have been favored by drag racers for many years but the trend is toward the radial type, which is used for endurance engine.

Seen here is the mode of operation for both vertical and radial gas ports. The vertical gas ports have been favored by drag racers for many years but the trend is toward the radial type, which is used for endurance engines. You may have heard the term "gas porting," but may not be too sure what it means. This is a technique to back up the top ring with combustion chamber pressure so that the ring is more firmly pressed against the bore. There are two types of gas ports, those that pass down through the crown of the piston and those that are located radially intersecting the top surface of the top ring groove. The radial-style gas ports are common for long-distance race engines. The current trend is to use radial gas ports as they seem to be as effective, but do not unduly accelerate ring and bore wear at TDC. With a good race blend or street synthetic, bore wear at TDC is not really an issue. I have just completed a 1,000-mile endurance test with the new Joe Gibbs Racing race oil and the rings of the gas ported JE pistons in my Cup Car engine wore less than three tenths of a thousandth off the surface. This amount of wear led to the ring gap getting bigger by only about 1 thousandth. An oil analysis at the 100- and 1,000-mile point indicated that most of the wear took place in the first 100 miles. This indicates that the ring and oil combination could be good for as much as 10,000 race miles.

COMPRESSION RATIO DEFINITION :

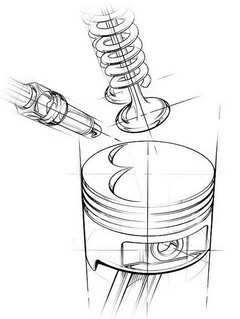

The CR is the ratio of the volume above the piston at BDC (left) compared to the volume at TDC (right). The formula for the CR is (V+C)/C. In this formula, V is the swept volume of the cylinder (i.e. the cylinder's displacement in cubic centimeters or cc) and C the total combustion chamber volume (in cc) when the piston is at TDC.

An example would look like this: say the volume above the piston at BDC is 110cc with 100cc being the displacement volume (V) due to piston motion and 10cc the total combustion space (C) remaining at TDC. When the contents of the cylinder at BDC are squeezed into the 10cc remaining at TDC, the charge occupies 1/11th of the space so the CR is 11:1. To find out what total combustion chamber cubic centimeters are required for the CR, you want subtract 1 from that ratio and divide the result into the displacement volume of the cylinder.

FOUR-STROKE FUNCTION :

From left to right we have the intake, compression, power, and exhaust strokes of a four-stroke or four-cycle engine. On the induction stroke, a fresh air/fuel charge is pulled past the open intake valve as the piston moves down the bore. At around Bottom Dead Center (BDC) the intake closes and the piston motion moving up the bore starts the compression stroke. At some point just before the piston reaches the top of the compression stroke at Top Dead Center (TDC), the spark plug will fire. At this point there is a small delay in the combustion before it really gets underway (hence the firing a little before TDC). As the piston goes over TDC so the combustion event burns the charge and the heat generated causes the contents of the cylinder to rapidly rise in pressure. This pressure pushes the piston down the bore on the power stroke. As the piston approaches the end of the power stroke, the exhaust valve starts to open. Initially the gases, still at relatively high pressure, vent themselves out through the progressively opening exhaust valve. By the time the piston starts to move up the bore the exhaust valve is already well off its seat. After this initial cylinder "blow down," the piston's motion up the bore pushes out the remaining spent charge through the exhaust valve. At the top of the exhaust stroke the intake begins to open and the whole sequence of events starts over again.

Compression & Cylinder Pressure :

Raising the CR increases torque, and consequently power, throughout the rpm range. Because raising the CR increases thermal efficiency, it brings about an increase in fuel economy. If a longer duration cam is installed, raising the CR at the same time can be worth considerably more than these two moves considered separately. When the CR is raised, peak combustion pressures are increased. And since cylinder pressure equals torque, that's a good thing. A rule of thumb for typical production engines is that combustion pressure is equal to the CR times 100. This tells us that, from a 10:1 engine, we would expect to see about 1,000 psi of peak combustion pressure. For a well-developed high-performance engine, combustion pressures can be as much as the CR times 120.

Date de création : 29/12/2009 @ 20:00

Dernière modification : 30/12/2009 @ 01:35

Catégorie : Technique automobile

Page lue 30402 fois

Imprimer l'article Imprimer l'article

| |